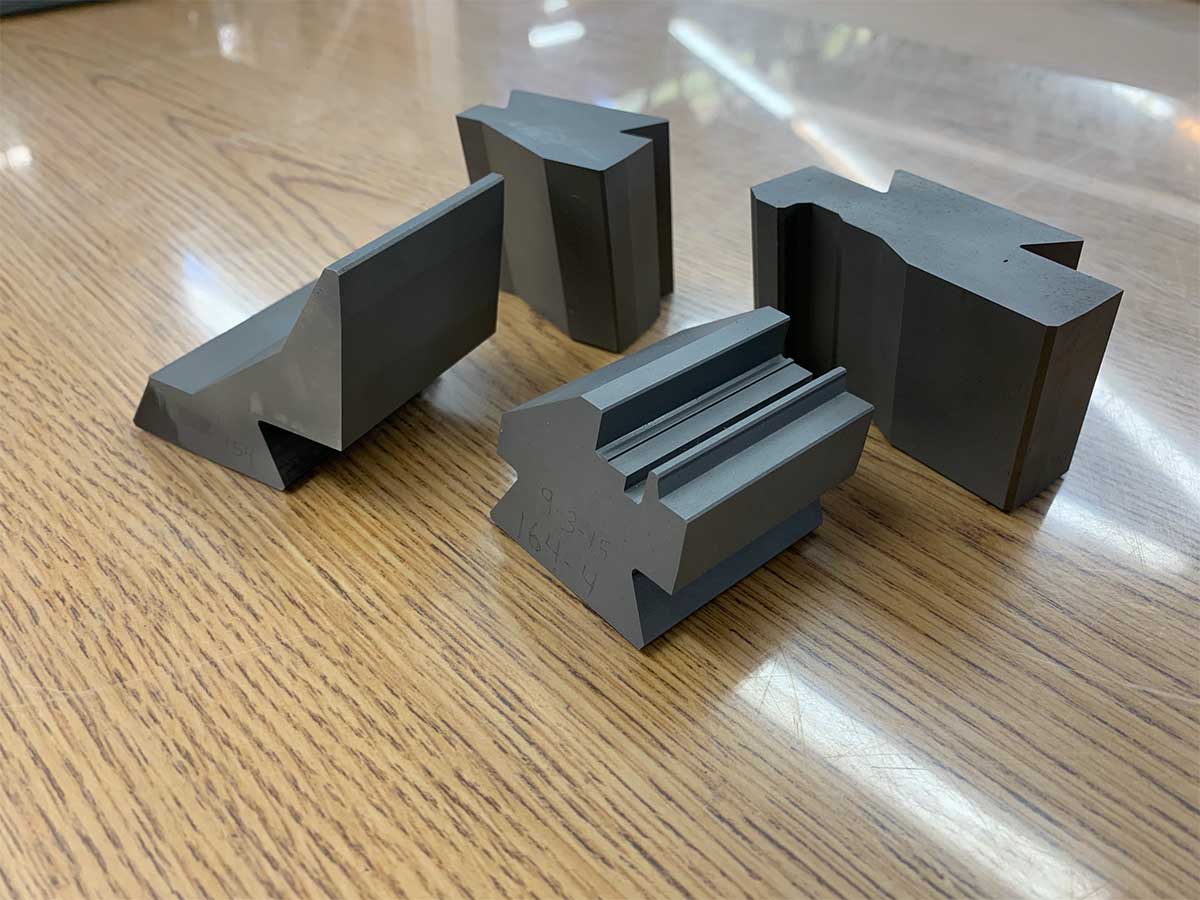

Wire Electrical Discharge Machining

ICC holds extensive expertise in Screw Machining, Hydraulic Service & Repair, Gearbox Service & Repair, etc. For example, Wire Electrical Discharge Machining (EDM) is an advanced machining process that depends on a precise application of electrical sparks to produce a desired shape or finish on a workpiece. Wire EDM (WEDM) is a variation of the EDM machining method that is primarily used for forming ties, cutting plates or tools. In addition, EDM can be used to form punches from harder metals that are typically not conducive to standard machining processes.